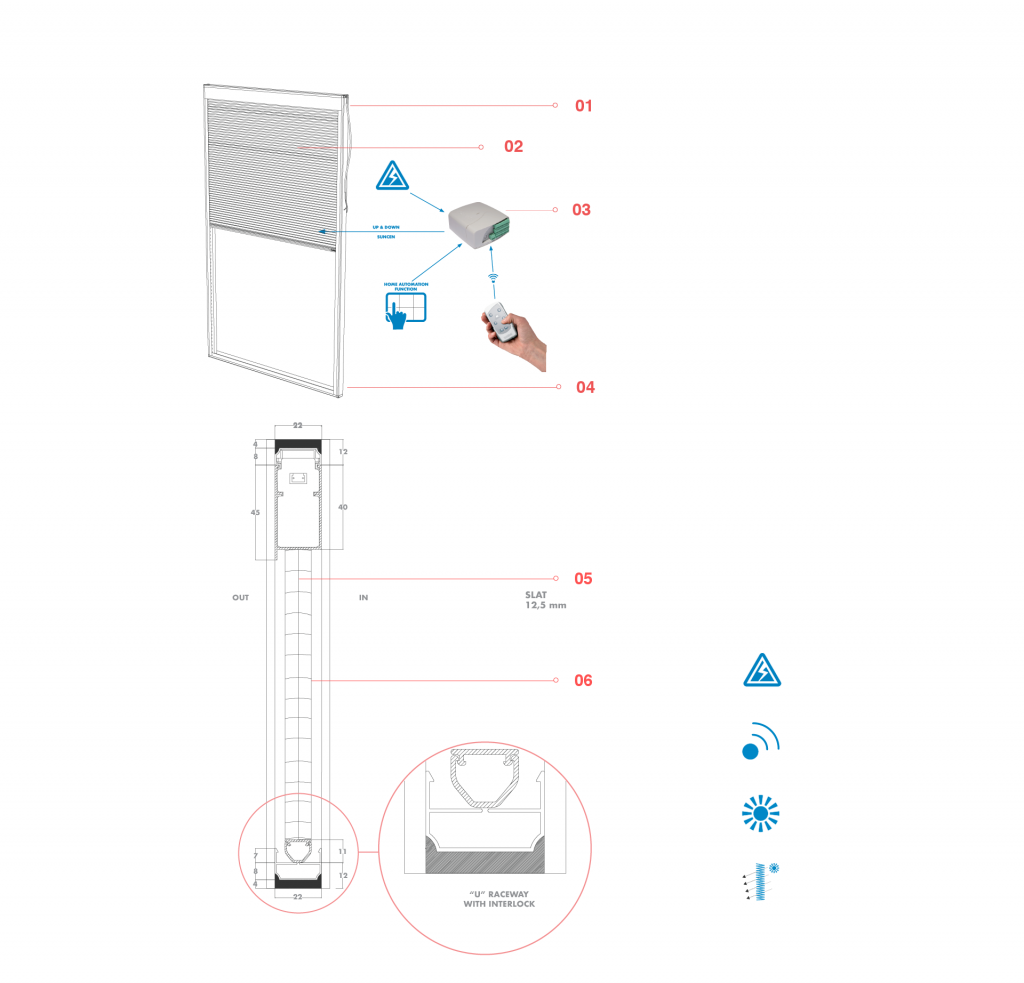

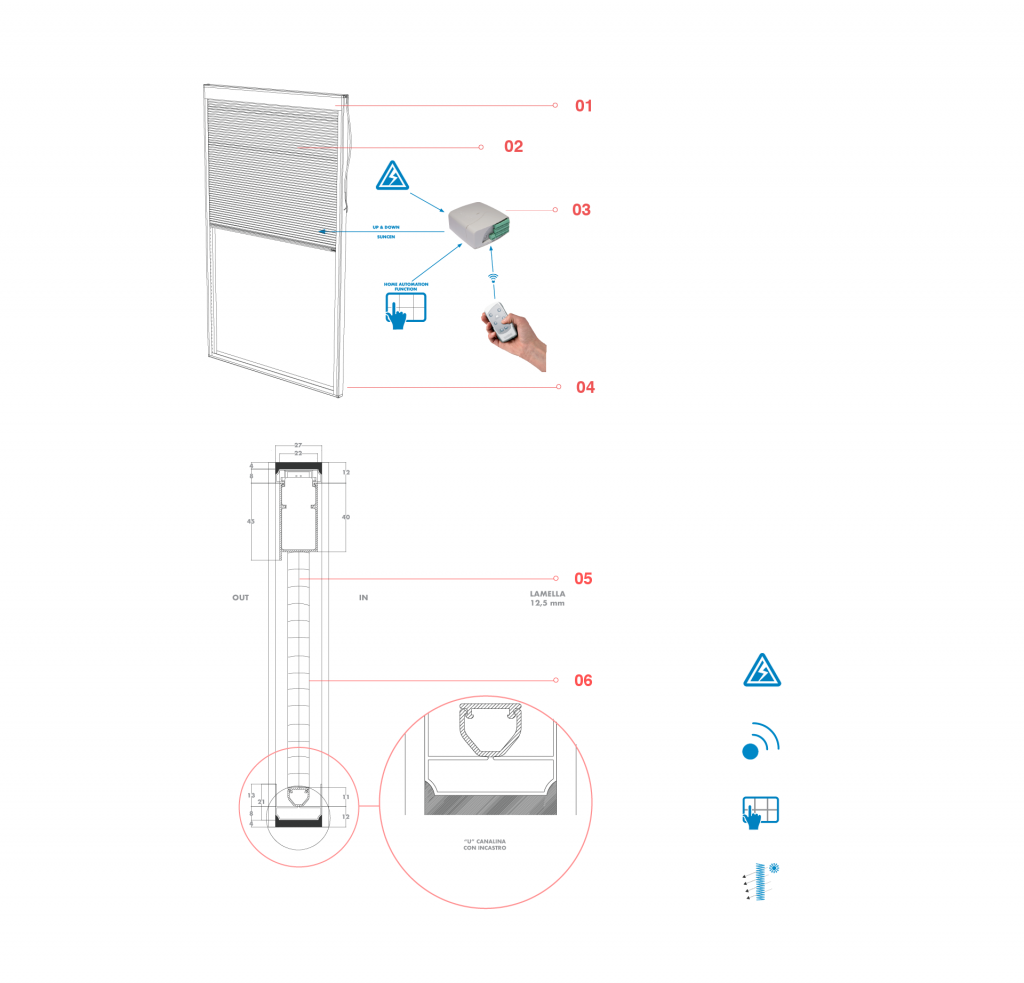

Venetian

Venetian blind in double glazing with control unit with 2-4-6-8-10-12 channels which allows moving single and/or group movement of blinds automatically or manually through wall buttons. Great versatility of the system thanks to the small section of wires to use, the great distance of the control unit

from the connected blinds, the possibility of having the version with radio receiver to use remote radio control as well, possibility of connection to the home automation system. Simple electrical connection and clear and intuitive functioning of the system.